SF6 Leak Detection 101: The Impact of Gas Safety

Recently, the significance of safety regarding gas leaks has taken a prominent position, particularly in fields that utilize greenhouse gases like SF6. This gas is exceptionally effective for electrical insulation in electrical equipment, but poses major environmental issues if leaked into the air. As the urgency to combat climate change increases, organizations are seeking new solutions to detect and address SF6 releases more successfully.

Enter the SF6 leak detection camera, a groundbreaking tool designed to boost safety and environmental stewardship. These specialized cameras employ modern technology to identify the existence of SF6 gas, making it easier for technicians to identify leaks quickly and precisely. By providing a visual depiction of gas emissions, these cameras are changing the way utilities and industries oversee SF6, paving the way for safer operations and compliance with strict environmental standards.

Grasping Sulfur Hexafluoride (SF6) together with The Risks of Dangers

SF6, also referred to as SF6, can be depicted as a colorless, scentless gas widely utilized in electrical equipment as an electrical insulator as well as arc extinguishing medium. It is preferred due to its excellent electrical insulation characteristics and notable reliability, making it ideal for uses in high-voltage switches and additional elements in electrical grids. Despite the fact that SF6 significantly enhances security and efficiency in electrical systems, its potent impact as a greenhouse gas have generated environmental issues.

In spite of its merits in the electrical industry, SF6 is regarded as one of the strongest greenhouse gases, possessing a potential for global warming many times higher than that of carbon dioxide throughout a century. This brings up significant worries about its leakage into the atmosphere. Small traces of SF6 can have a large impact to earth's changing climate, resulting in increased scrutiny of its application and the importance of efficient detection techniques for leaks.

Identifying SF6 leakage is essential for both safeguarding ecology and operational safety. Traditional methods of identifying leaks can be labor-intensive and might miss some leaks. As the emphasis on sustainable practices grows, advanced technologies, like SF6 SF6 detection cameras, are emerging as vital resources for identifying and reducing leaks, ensuring both adherence to rules and a dedication to environmental responsibility.

How Leak Detection Cameras Function

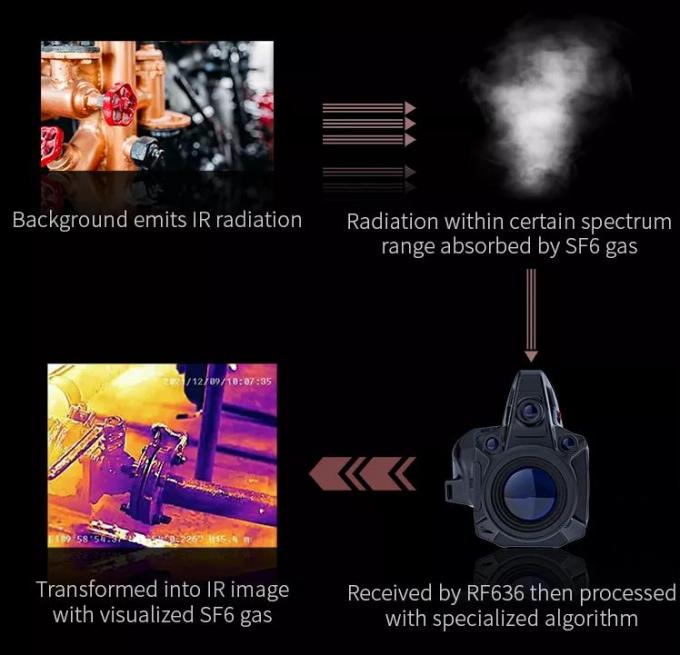

SF6 leak detection camera s make use of sophisticated infrared technology to recognize the occurrence of sulfur hexafluoride gas in the atmosphere. These cameras are armed with specialized sensors that identify the specific infrared signature given off by SF6, letting them to visualize gas leaks even in subtle concentrations. By capturing this signature, the cameras can produce a clear image of the gas, enabling operators to swiftly locate and fix leaks.

The operation of these cameras is rooted in the principle that gases capture and emit infrared radiation at particular wavelengths. When an SF6 leak happens, the camera detects the infrared radiation connected to the gas and highlights it on the display. This instantaneous visualization is crucial for guaranteeing safety and maintaining equipment integrity, as it enables quick action to be taken when leaks are identified.

In addition to real-time detection, SF6 leak detection cameras often feature features that enhance their usability, such as thermal imaging technology and data logging. The use of thermal imaging helps to differentiate gas leaks from other environmental factors. Data logging allows operators to maintain records of leak positions and concentrations, facilitating ongoing monitoring and maintenance efforts to ensure compliance with safety regulations and ecological standards.

Benefits of Visual Technology in Gaseous Safety

The implementation of camera technology in gas security, specifically for sulfur hexafluoride leak detection, delivers numerous benefits that enhance and efficiency and precision. One of the main benefits is the potential to deliver immediate visual monitoring of gas leaks. Conventional approaches often depend on manual inspections, which can be time-consuming and may not reach all zones effectively. With gas leak cameras, personnel can assess large areas quickly and detect fugitive emissions that might otherwise go overlooked. This proactive approach greatly decreases response times to gas leaks, mitigating potential hazards.

Another notable benefit is the ability to capture high-resolution pictures and videos of leaks. This visual data not only aids in timely detection but also acts as critical documentation for further examination and reporting. Detailed visual documentation can help repair teams comprehend the character and scale of a leak, facilitating more effective choices regarding repairs or system upgrades. Moreover, employing camera systems can support adherence with safety regulations and sector standards, as organizations can demonstrate their due diligence in monitoring gas security.

Finally, the use of sulfur hexafluoride gas leak cameras supports healthier working environments for workers. Since these cameras can be operated from a remote location, they reduce the requirement for workers to enter potentially hazardous areas during gas assessments. This remote ability reduces exposure to dangerous gases and adds to the overall safety environment within companies. By utilizing cutting-edge camera systems, organizations not only protect their workforce but also bolster their operational integrity and environmental stewardship.